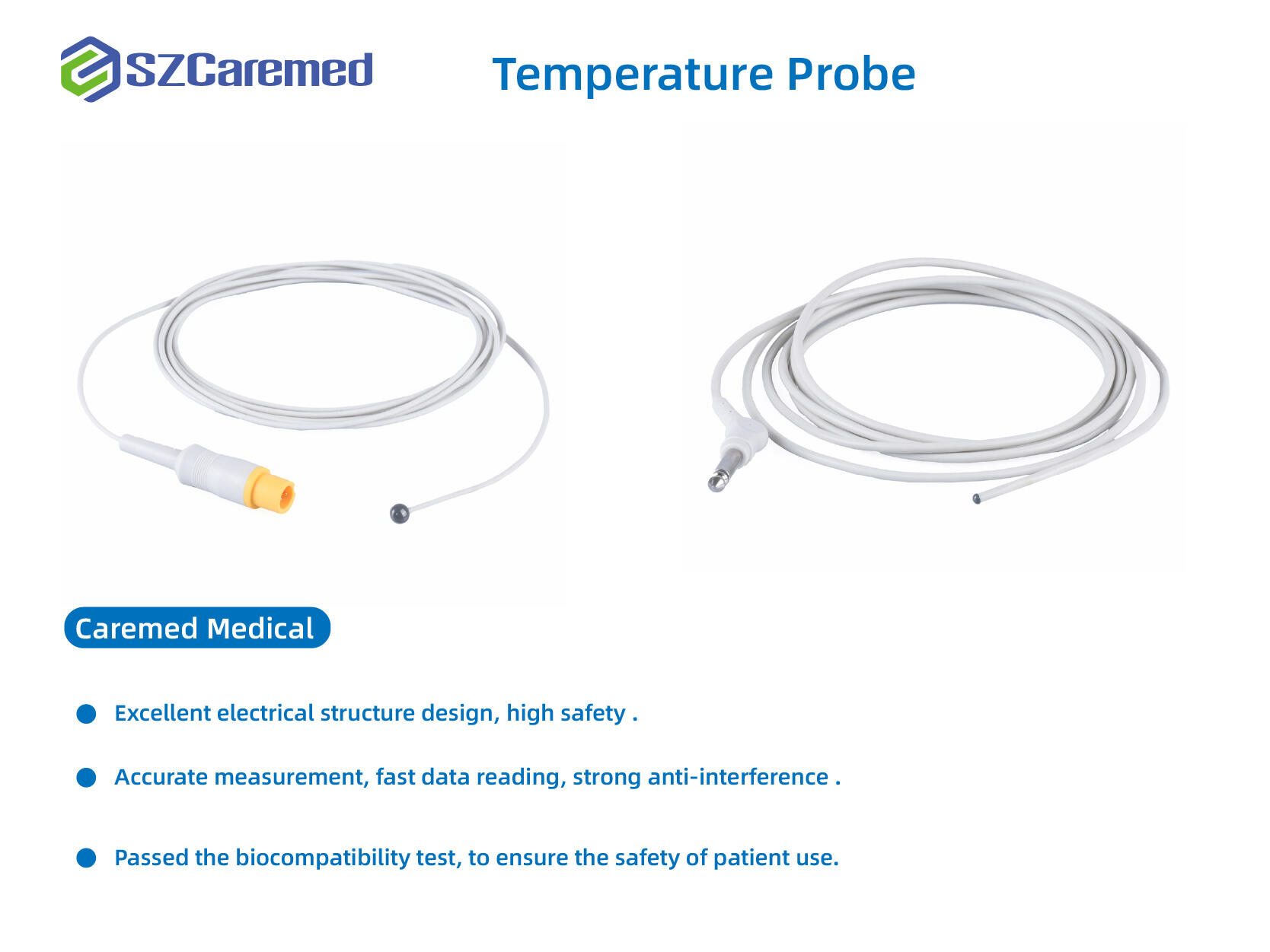

Core Factors in Temperature Probe Selection

Accuracy and Measurement Consistency

In industries like healthcare and manufacturing, ensuring accurate temperature measurements is crucial, as even minor inaccuracies can lead to significant discrepancies in outcomes or product quality. For instance, an inaccurate temperature reading in a medical setting might impact patient diagnosis or treatment. Equally important is measurement consistency, which helps in providing reliable data analysis across different applications. Adhering to industry standards, such as ISO 17025, guarantees that measurement accuracy is at an acceptable rate, ensuring uniformity. Calibration processes play a vital role here, as they help in maintaining accuracy over time by correcting sensor drift, ensuring the data remains precise and consistent through regular checks and adjustments.

Temperature Range and Response Time

The temperature range of a probe determines its suitability for various applications, from cryogenics to high-temperature industrial processes. Selecting the appropriate probe requires understanding the temperatures involved, as each sensor type has its own range capabilities. For example, thermocouples are well-suited for high-temperature environments, whereas Resistance Temperature Detectors (RTDs) are more effective for lower temperatures due to their precision and stability. Similarly vital is the response time, which affects a monitoring system's effectiveness, particularly in dynamic environments where swift temperature changes occur. A fast response time ensures that the system can quickly adapt, providing real-time data essential for process control and safety.

Environmental Resilience

Temperature probes must withstand varied environmental conditions to function effectively without degradation. This includes resistance to humidity, pressure, and exposure to corrosive substances which can affect the probe's performance. Materials and coatings, such as those made from stainless steel or specialized plastics, enhance a probe's environmental resilience. These materials offer moisture resistance and corrosion protection, extending the lifespan of the probes. Studies have shown that probes inadequately designed to handle environmental stressors often lead to compromised data accuracy and shortened operational life, underscoring the importance of considering environmental factors in probe selection.

Understanding Sensor Types and Their Applications

Thermocouples for High-Temperature Industrial Use

Thermocouples are indispensable for high-temperature industrial applications, owing to their robust performance and cost-effectiveness. They operate by measuring the voltage differences between two distinct metals, making them ideal for extreme environments like metal processing or aerospace sectors. Typical types, such as Type K and Type J, are popular choices. Type K thermocouples, for instance, cover a broad temperature range, extending from -200°C to 1260°C, making them reliable for dynamic industrial settings. Type J thermocouples, while slightly limited, still cater effectively to more moderate temperature needs, offering insights into optimal sensor selection based on usage scenarios.

RTDs vs. Thermistors: Precision vs. Affordability

Resistance Temperature Detectors (RTDs) and thermistors are two of the most common sensors used for precise temperature measurement. RTDs boast high precision due to their stable resistance properties and are thus favored in laboratories and high-tech industries. They excel in applications requiring accuracy, such as scientific research. Conversely, thermistors are valued for their affordability and rapid response times, especially used in consumer electronics where cost efficiency is critical. RTDs are preferred for applications with stringent accuracy requirements across hotter temperature ranges, while thermistors offer a budget-friendly option for everyday devices operating within lower temperature confines.

Infrared Sensors for Non-Contact Applications

Infrared sensors are pivotal for non-contact temperature measurement applications, offering significant advantages in safety-critical environments. These sensors detect infrared radiation emitted by objects, making them invaluable in the healthcare sector for fever screening and manufacturing for parts inspection without physical interaction. Non-contact measurements minimize contamination risks and enhance operational safety, substantially useful in areas where direct contact is impractical or unsafe. Industries harnessing infrared technology, such as automotive manufacturing and food processing, underscore its transformative role, where precision and safety are paramount. This highlights the sensor’s versatility and indispensable contribution to modern temperature monitoring systems.

Environmental and Operational Considerations

Compatibility with Liquids, Gases, and Solids

Probes must be designed to interact effectively with their medium, be it liquids, gases, or solids, considering factors such as pressure and viscosity. The design of these probes varies significantly to accommodate different physical properties, ensuring accurate measurements. For instance, in industries such as oil and gas, pressure sensors are tailored to withstand high-pressure environments, while viscosity-related probes are crucial in chemical manufacturing where fluid properties dictate processing conditions. Proper selection ensures reliable data collection, critical for maintaining operational efficiency and safety standards in these sectors.

Impact of Moisture and Corrosive Agents

Moisture and corrosive elements can significantly degrade sensor performance and lifespan, making it essential to choose materials that resist these conditions. Different materials, such as stainless steel or high-grade plastics, offer varying degrees of resistance against environmental degradation. An example can be seen in marine applications, where sensors need to withstand salty and humid conditions. Industry reports often highlight the costly implications of sensor failures caused by corrosion, emphasizing the need for robust designs. By utilizing corrosion-resistant materials, organizations can mitigate these risks, ensuring longer sensor life and reducing replacement costs.

Integration with Systems Like EEG Electrodes or Oxygen Sensors

The seamless integration of temperature probes with systems such as EEG electrodes or oxygen sensors is crucial for accurate data collection and efficient operations. This integration requires adherence to industry protocols that minimize interference and enhance data accuracy. For example, medical environments often rely on harmonized systems to provide consistent patient monitoring, where devices like temperature probes, EEG electrodes, and oxygen sensors must operate synchronously without data corruption. By following industry standards, manufacturers can ensure their products integrate seamlessly, thus becoming indispensable in sectors demanding precision.

Cost-Benefit Analysis for Long-Term Use

Initial Investment vs. Maintenance Costs

Understanding the balance between initial investment and ongoing maintenance costs is crucial for industries relying on temperature probes. The initial purchase price includes the cost of sophisticated technology that ensures accurate measurements in complex environments. Maintenance costs, on the other hand, often encompass calibration, regular checks, and part replacements. For instance, industries that invest in high-quality temperature probes might face higher upfront costs, but these can lead to significant savings over time due to reduced repair needs and enhanced durability. A case study in the chemical sector demonstrated long-term savings where companies opting for premium probes saw a drop in maintenance costs by 25% over five years, justifying the initial investment. Hence, investing more initially in cutting-edge technology can often prevent higher future expenditure, making it a wise decision for many sectors.

Calibration Requirements and Lifespan

Temperature probes require regular calibration to maintain their operational efficiency, which is a critical factor in long-term usage. Calibration ensures that the sensors continue to deliver precise readings, vital for both industrial and medical applications. Most temperature probes need recalibration multiple times throughout their operational lifespan, which averages five to ten years for quality models. For example, high-end probes used in laboratories or manufacturing processes may require semi-annual calibration to adhere to strict accuracy standards. This regular maintenance directly impacts operational efficiency and affects overall cost forecasts by ensuring measurements remain reliable over time. Therefore, understanding the calibration needs and expected lifespan of probes is paramount in calculating their cost-benefit ratio in long-term scenarios.

Industry-Specific Needs (Medical vs. Manufacturing)

Temperature probes serve diverse purposes across sectors, with the medical industry and manufacturing having distinct needs. Medical applications demand extremely accurate and reliable readings due to clinical implications, governed by strict regulations from entities like the FDA. These probes must comply with health safety standards, often requiring thorough calibration and consistent performance. Conversely, manufacturing may prioritize probes resilient to harsh environments that meet ISO standards for durability and accuracy. Industries like electronics manufacturing depend on probes to maintain precise conditions in production processes, where regulatory compliance plays a pivotal role in selecting sensor technology. Hence, whether in healthcare or manufacturing, temperature probes must meet specific requirements tailored to their sector to ensure regulatory adherence and optimal function.

Installation and Maintenance Best Practices

Proper Probe Placement Techniques

Accurate probe placement is crucial for obtaining reliable readings, whether in a medical or industrial context. It is vital to adhere to specific practices that ensure precision and consistency. One fundamental aspect is to thoroughly assess the environmental conditions and anatomical landmarks, as these factors significantly influence measurement accuracy. In medical applications, for instance, a temperature probe should be placed in areas that closely reflect the core body temperature, like the rectum or esophagus, for precise assessments. Conversely, in industrial environments, careful placement according to the proximity to heat sources or vents is critical. For complex setups, visual aids such as diagrams can be invaluable tools for correctly positioning probes, ensuring that users have a clear understanding of the necessary steps.

Avoiding Signal Interference in EKG Cables and Similar Setups

Signal interference is a common challenge during the installation of EKG cables and similar systems, which can significantly impact the accuracy of readings. To mitigate these issues, it's essential to identify potential sources of interference such as electromagnetic fields from nearby devices or improper cable management. Ensuring that EKG cables are properly shielded and routed away from these interference sources is a critical step. Additionally, maintaining adequate separation between the cables and other electronic devices can greatly enhance signal integrity. Regular checks and maintenance, including inspecting cables for wear and tear and ensuring secure connections, are also pivotal in avoiding signal disruptions. By implementing these strategies, one can significantly improve the reliability of measurements in EKG and similar setups.

Troubleshooting Common Sensor Failures

Understanding common sensor failures and how to effectively troubleshoot them is essential for maintaining operational efficiency. Some typical issues include mechanical damage, faulty connections, and calibration errors. To address these effectively, a step-by-step approach is recommended. Start by visually inspecting the sensor and its connections for any physical damage, ensuring all connections are secure. Next, verify calibration settings, as inaccurate calibration can lead to faulty readings. For more persistent issues, consulting a troubleshooting flowchart can streamline the diagnostic process and provide clear guidance on steps to take, such as resetting the device or replacing specific components. Regular maintenance and timely troubleshooting can significantly reduce downtime and improve sensor longevity, ensuring consistent performance.