News

What certifications are necessary for ECG cables to enter global markets?

Core Regulatory Frameworks for ECG Cable Certification

The Role of International Certifications in Medical Device Compliance

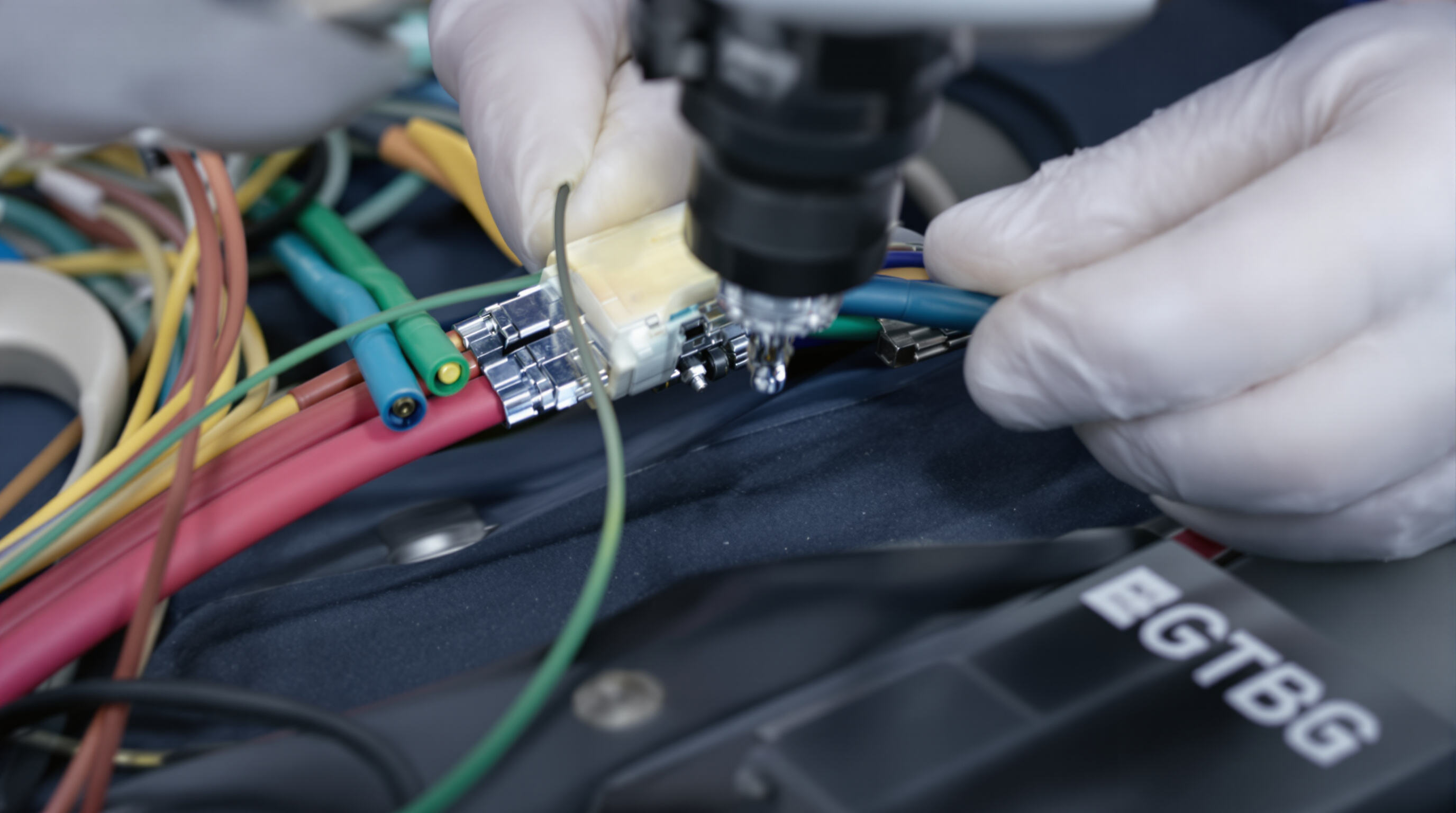

Certifications from international bodies set the minimum safety and performance requirements for ECG cables, making sure they work properly when used around the world in different hospitals and clinics. According to research published by Deloitte last year, nearly four out of five recalled medical devices had issues related to missing or incomplete certification documentation. That's why getting proper certification matters so much these days. The tests actually check if the cables are safe electrically, transmit signals accurately without interference, and made from materials that won't cause reactions inside patients' bodies. All these aspects matter greatly when doctors need accurate readings during critical moments in patient care situations.

Overview of Key Regulatory Bodies Governing ECG Cable Standards

| Region | Regulatory Bodies | Core Standards | Key Requirements |

|---|---|---|---|

| North America | FDA, Health Canada | 21 CFR Part 890, CSA C22.2 No. 601 | Signal integrity testing, EMI/RF immunity |

| European Union | EU MDR, Notified Bodies | EN 60601-2-25, ISO 13485 | Biocompatibility, sterilization validation |

| Asia-Pacific | PMDA, NMPA | JIS T 0601, GB 9706.1 | Durability testing, lead insulation checks |

Why ECG Cables Require Specialized Regulatory Approval

Because ECG cables come into direct contact with patients and play such an important part in diagnosing serious conditions, they undergo much tougher regulation compared to regular medical accessories. These cables need to meet several important standards. For example, there's ISO 10993-5:2018 which deals with whether materials are harmful to cells, IEC 60601-2-27 that sets specific performance requirements for ECG devices, and in the United States, 21 CFR 870.2340 covers electrical safety issues. Looking at data from around the world, about 62 percent of all certification holdups happen because companies didn't properly validate their materials. This problem is particularly common with reusable cables that get disinfected over and over again during normal hospital operations.

FDA 510(k) Clearance and U.S. Market Entry for ECG Cables

FDA Class II Medical Device Classification for ECG Cables

Under FDA rules, ECG cables fall into the Class II category of medical devices, which means manufacturers need to submit a premarket notification (the so-called 510(k) process) before they can market these products. This particular classification indicates that there's a moderate level of risk involved, so testing becomes necessary across several key areas including electrical safety checks, biocompatibility assessments, and ensuring that signals remain intact during operation. Meeting certain standards recognized by the FDA like IEC 60601-1 for electrical equipment safety and ISO 10993-5 regarding biological evaluation of medical devices isn't just recommended it's absolutely required if companies want their products cleared for sale in the US market.

510(k) Clearance Process and Performance Benchmarks for ECG Cables

Manufacturers seeking 510(k) clearance need to demonstrate that their product is substantially equivalent to an already approved medical device on the market. The main performance requirements focus on several critical areas. Electrodes should stick well enough with at least 1.5 Newtons per square millimeter of adhesion strength. Signal quality matters too, needing to keep noise below 5 microvolts. Impedance levels across different leads shouldn't vary by more than 3 percent. When preparing submissions, companies must provide solid test results showing how durable the devices are mechanically, typically surviving over 10,000 flex cycles. They also need to meet electromagnetic compatibility standards according to EN 60601-1-2 regulations. These requirements ensure both safety and effectiveness throughout the product lifecycle.

Common Pitfalls in U.S. Regulatory Submissions for ECG Cables

When companies submit medical device applications, incomplete biocompatibility information often causes problems, especially when they miss out on proper chemical characterization according to ISO 10993-18 standards. Another common issue is when the device comparison doesn't match up properly with existing products. The latest FDA Compliance Review from 2024 showed pretty shocking numbers actually, about one third of all first time submissions got rejected simply because there wasn't enough documentation regarding electrical safety requirements. To speed things along, manufacturers should really think about doing thorough gap analysis before submitting anything. Working with outside labs for testing also makes a big difference. Devices that pass on the first try typically get approved within around 132 days. But if changes are needed after review, the whole process stretches out to about 210 days instead.

CE Marking and EU MDR Compliance for ECG Cables

Transition from MDD to MDR: Impact on ECG Cable Certification

When the EU moved away from the old Medical Devices Directive (MDD) to implement the new Medical Device Regulation (MDR) 2017/745, it basically made getting certified much harder for medical equipment makers. Products that were already on the market under MDD rules now face stricter demands around tracking where things come from, doing better clinical assessments, and keeping tabs on how they perform after sale. Most manufacturers have until May 2025 to get their existing products up to speed with these new standards. For ECG cable producers specifically, this means going through the whole certification process again if they want to keep selling in Europe with that CE mark everyone looks for. The clock is ticking pretty fast here for companies trying to maintain their presence in the EU market.

Essential Requirements for ECG Cables Under EU MDR 2017/745

Under MDR, ECG cables must demonstrate compliance with:

- Biocompatibility per ISO 10993 series for skin-contact materials

- Electrical safety, limiting leakage currents to ≤10 µA (IEC 60601-1)

-

Signal accuracy within ±5% tolerance for waveform reproduction (IEC 60601-2-25)

Additionally, manufacturers must implement a Unique Device Identification (UDI) system and provide clinical evidence of performance equivalence.

Notified Body Involvement in CE Certification of ECG Cables

Most ECG cables fall under Class IIa or higher and require assessment by a Notified Body. For reusable or measuring-function cables, these bodies evaluate sterilization protocols and calibration procedures. Even Class I non-sterile cables must maintain full technical documentation, including risk management per ISO 14971 and post-market performance reporting.

Critical ISO and IEC Standards for Global ECG Cable Certification

ISO 13485:2016 and Quality Management for ECG Cable Production

Following ISO 13485:2016 standards is pretty much a must do when making medical grade ECG cables. The standard sets up quality management systems or QMS for short, which basically means everything gets tracked properly, risks are managed, and production stays consistent from batch to batch. Most regulators care about this stuff too. Around 7 out of 10 regulatory bodies actually look at whether companies have ISO 13485 certification when they check products for market approval. They see it as proof that manufacturers follow good practices, especially important parts like those little but crucial connectors and insulation materials that make sure the signals stay clean and safe.

ISO 60601-1 Compliance for Electrical Safety in ECG Cables

Meeting the standards set by ISO 60601-1 isn't just recommended but actually necessary for keeping patients safe when they're being monitored for heart conditions. The main things manufacturers need to focus on are making sure leakage current stays below those 10 microamp thresholds and that insulation resistance doesn't drop under 50 megaohms. These protections really help prevent problems caused by electromagnetic noise and unexpected power spikes that could otherwise disrupt readings. What we've seen recently is a push towards better shielded cables as well. This makes all the difference in today's world where wireless signals are everywhere, especially around places like MRI suites where interference can be particularly problematic for accurate monitoring.

IEC 60601-2-25: Specific Safety Requirements for ECG Cables and Leads

The IEC 60601-2-25 standard sets out what makes ECG cable assemblies perform well, looking at things like how much force they can handle before bending (no more than 25 Newtons) and how long connectors will last after being plugged and unplugged over 10 thousand times. Some research from 2023 found that when hospitals used cables meeting these standards, there were about 34 percent fewer problems with movement causing bad readings compared to cheaper cables that didn't meet the requirements. For companies making medical equipment, getting their products tested according to IEC guidelines is pretty much essential if they want to sell globally. Most regulators around the world only accept certifications from tests done following these specific procedures.

Country-Specific Certification Pathways for ECG Cables

Health Canada Licensing for ECG Cables in the Canadian Market

In Canada, ECG cables fall under the category of Class II medical devices according to the Medical Devices Regulations (SOR/98-282), which means they need special licensing from Health Canada before going on the market. Companies applying for these licenses have to show they meet certain standards too. The main ones are IEC 60601-1 when it comes to making sure everything is electrically safe, plus ISO 13485 for managing quality throughout production. Looking at recent trends, there was actually a problem spotted back in 2023 where about one third of applications coming from outside Canada got stuck waiting because their biocompatibility testing wasn't complete enough. That kind of delay can really slow things down. Fortunately, joining what's called the Medical Device Single Audit Program (MDSAP) helps speed up the whole process since this program basically creates common rules for quality management systems across multiple regions including Canada itself, the United States, European Union countries, Australia, and even Japan. So manufacturers who participate save time and money in the long run.

Japan's PMDA Approval and the JIS T 0601 Series for ECG Cables

The Pharmaceuticals and Medical Devices Agency in Japan, commonly known as PMDA, has set strict guidelines requiring adherence to JIS T 0601-1:2022 standards. This includes making sure devices properly handle motion artifacts during clinical validation processes. When it comes to electromagnetic compatibility testing, organizations such as the Japan Inspection & Certification Network (JICN) step in to evaluate how well equipment withstands interference. Their tests go all the way up to plus or minus 8 kilovolts for contact discharge scenarios. Looking at recent data from PMDA's 2024 report reveals some concerning numbers: nearly four out of five foreign manufacturers had to take corrective measures after their products failed lead durability checks according to JIS T 2315:2021 specifications. These findings highlight ongoing challenges faced by international companies trying to meet Japanese regulatory requirements.

China NMPA Registration and Mandatory Inspection of ECG Accessories

The National Medical Products Administration in China, known as NMPA, put into place regulations under GB 9706.1-2020 that require medical devices to undergo 168 hours of lead immersion testing when exposed to temperatures around 41 degrees Celsius. Last year saw another important change where factories producing Class II cables must welcome inspectors right at their production sites. According to reports from Asia Regulatory Journal, nearly six out of ten inspections found problems with how companies kept track of insulation resistance measurements. And things don't stop there after products hit the market either. Regulators are now collecting actual usage data from these devices during approximately 1,000 hours of operation across various third-tier hospitals throughout the country.

FAQs

What are the key international certifications required for ECG cables?

Key international certifications include ISO 13485 for quality management systems, IEC 60601-1 for electrical safety, and ISO 10993 for biocompatibility assessments.

Why is FDA 510(k) clearance important for ECG cables?

FDA 510(k) clearance is crucial for ECG cables as it ensures the product is substantially equivalent to already approved devices, deeming them safe and effective for the US market.

How does the transition from MDD to MDR affect ECG cable certification in the EU?

The transition to MDR involves stricter requirements for clinical assessments, tracking, and post-market performance, making certification more challenging yet crucial for CE marking.

What role do notified bodies play in the CE certification of ECG cables?

Notified bodies assess ECG cables belonging to Class IIa or higher, evaluating sterilization protocols, calibration procedures, and verifying technical documentation for CE certification.

Which standards are critical for the international certification of ECG cables?

Critical standards include ISO 13485 for quality management, IEC 60601-1 for electrical safety, and IEC 60601-2-25 for performance benchmarks essential for global certification.

ONLINE

ONLINE